Grain Bin 101: Key Factors Encircling Grain Bin Selection

Most farmers have been through the process of purchasing a new grain bin, or have at least shopped around and scoped out prices. Each of those farmers has likely come to the realization that it’s not a small decision. Sifting through the sizes and types of bins, along with accessories and features, isn’t always cut and dry. Additionally, comparing bin to bin can be a tall order if you haven’t done your research or aren’t familiar with typical bin components or construction.

You want to be sure your final decision matches your farm’s needs and gives you the best return on investment. Here are a few key aspects to bear in mind as you go about selecting your storage system.

Selecting a Site

When selecting the site for a new grain bin, it’s easy to focus on today’s production and forget to factor in future growth. But as agriculture has evolved and seed varieties have improved, expected yields continue to grow. Planning for that growth or the growth brought about by farming additional land is critical to successfully selecting the best bin site.

Take, for example, a farmer who 20 years ago chose a bin site in an isolated spot with limited space. His 100 bushels per acre yield held steady for a number of years, so ideally he’d have no issues placing the bin in an area with limited space.

No issues. Except for the change that takes place over the next several decades while the bin holds strong. Let’s say, for example, that during that time the per-acre yield has jumped from 100 bushels to 150. Since there’s no room for a second bin at the original site, the farmer will need to put a second bin at a different site. That could require installing a separate electrical system, which could be costly. If the farmer had, instead, erected his first bin in an area with plenty of space, he would avoid that cost.

On the other hand, expansion is easy when it’s planned right. Not only should you evaluate whether trucks will have the necessary space to maneuver around, but also be sure the bin site offers expandability, too; leave room for a second, third, or fourth bin in the future.

The area surrounding the bin isn’t the only space to consider. Farmers also need to select the right size of bin.

Capacity

Expenses run high on a farm, which makes low-cost options appealing. But as you begin to compare different sizes of bins and the cost associated with each, minimizing costs by building small isn’t always a good option. Without enough bin space, your grain bin is likely to become your bottleneck and limit your profit potential.

Although it’s more costly upfront to get the larger bin, keep in mind the cost required to get crews to return and set up a second bin. You can easily and accurately calculate the bushels you will need to store by multiplying your farm’s acreage by average bushels. Again, leave room for future growth within the bin, or make sure

A lot of farmers subtract the amount they’ll be taking to the elevator from the projected storage space needed. For example, a farmer might estimate he’ll take in 30 percent of his crop and only will need to store 70 percent. In theory, this is great. But in reality this limits the farmer’s options in certain situations. For example, the elevator might decline the crop for any number of reasons. If that happens, where will he store the additional 30 percent?

Also remember a number of things are bound to change in the coming years:

- Farm expansion when a younger farmer takes the lead.

- Genetic improvements in seed or advancements in fertilizers.

- Marketing opportunities that come with holding grain back. Mill companies and elevators often offer a payout increase of several dimes per bushel to producers who agree to hold the grain at the time of sale, and deliver the grain in the spring.

As with any major purchase, the decisions don’t stop at the size and location of the bin. Just like when you’re buying a home, car, or tractor, there are other components, accessories, and construction elements to consider.

The Build, From Top to Bottom

Like anything that spends its life in the great outdoors, bins need to endure the heat of summer and the cold of winter. To withstand hail, snow, rain, and high winds, they have to be built solid or they simply won’t stand the test of time.

Roofs

Roofs take the harshest beating. In fact, 85 percent of bin damage involves the roof. Damage can include the roof caving in, blowing off or vent holes tearing. A strong roof is important in several ways. For example, if a sidewall begins to cave in and the bin has a strong roof, it’s easy and inexpensive to put a new sheet in. In the same scenario, a weaker roof will likely cave in along with the sidewall and cause an expensive, prolonged repair.

The design and construction of the roof are critical. Evaluate what each manufacturer offers for roof ribs and framing. Look for elevated roof ribs, up to 3.5 inches, that serve as rafters for the roof structure. Keep in mind roofs manufactured with additional breaks (or bends) in the metal have more strength.

Fastening

Fastening

Some manufacturers only use expansion bolts in the roof-ring construction. Though these bolts are nearly unavoidable in the industry, the roof ring can eventually twist or bend so much they can easily pop out of place. Therefore, when fastening a wind ring to the roof, be sure the ring is fastened with wind ring clamps at each roof rib, as well as clamping the wind ring together. Clamps are a stronger; more secure option because the wind ring acts as one structural unit.

Floors

The fabrication of the floor also can make a big difference in terms of the bin’s overall strength. Floor supports come in several different shapes and styles, so similar to the roof, look for floor supports with additional breaks in the metal for added strength. Floor supports can be up to four times stronger than others made of the same material based on how they are constructed.

Base Anchor

Base anchors secure the bin to the concrete, and anchors hold the bin down more securely. Extra strength in the bottom ring is a huge advantage, as it’s often a weaker point on bins. Some manufacturers build their bins with anchors as tall as 44 inches, which covers the entire bottom ring. The result is bottom ring strength equivalent to a ring that is two gauges thicker.

Poles Apart

Price is always a consideration when shopping for a bin, but to truly understand the price and make an apples-to-apples comparison; there are some details you need to consider carefully.

Narrow Core vs. Wide Core

Two companies might quote the same 36-foot-diameter by 10-ring-tall bin, but their capacities are off by 10,000 bushels and the prices vary just as much. When you investigate further, you might find one company quoted a narrow core and another priced a wide core.

So what’s the difference? Narrow core bins have more ribs and more ridges for the grain to sit on. Because of this, there is more down pressure on the bin when the  grain is flowing down. A wide core bin has fewer ridges with less area for grain to sit on, so there is less pressure when grain is flowing in.

grain is flowing down. A wide core bin has fewer ridges with less area for grain to sit on, so there is less pressure when grain is flowing in.

Unloading

A bin’s unloading system is one of the most important parts of grain equipment, and styles and options vary greatly. For example, an 8-inch unload tube is capable of releasing 2500 bushels per hour. A U-Trough design releases more than twice as fast, or up to 6000 bushes per hour. Be aware that the differences in cost and design are substantial. In addition, the unload tube forces grain through a tube that often damages the kernel, whereas the U-Trough and power sweep allow a free flow to help maintain the kernel condition. Be aware that the differences in design and cost are substantial; the price difference can be as much as $1000.

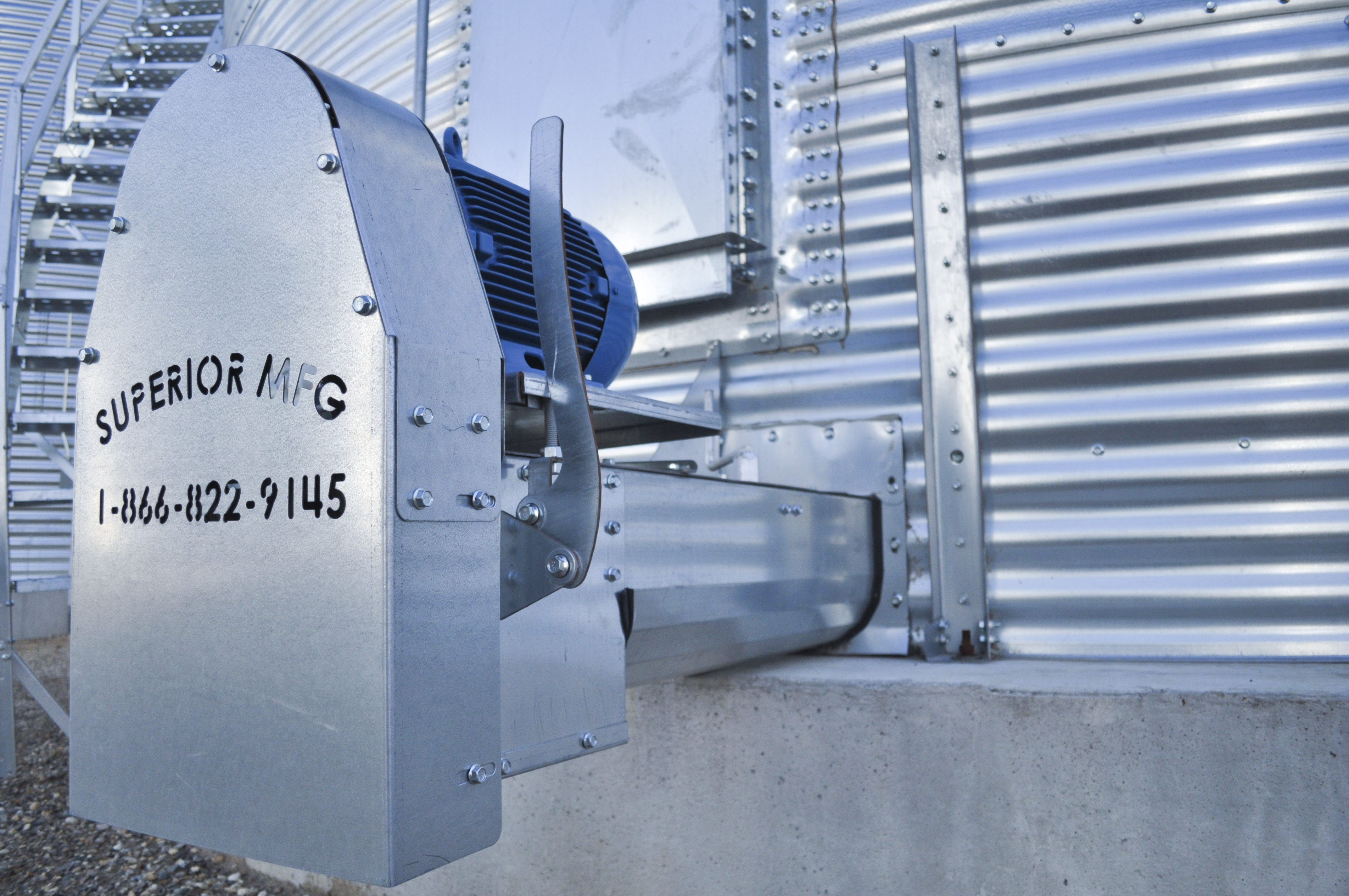

Fans

Even airflow through the grain bin is essential for proper cooling, storage, and air drying. Two types of fans are available. Vane-axial fans are better adapted to shallow-depth bin drying systems. They are generally lower in initial cost but are louder than centrifugal fans. Centrifugal fans are advantageous when relatively high air volumes need to be pushed through deep grain levels (12-20 feet) and are less expensive to operate.

Even the variance of the fans’ horsepower can be significant enough to become a major factor in your selection. Ask your grain bin manufacturer for an air flow chart to demonstrate the effectiveness of varying fan systems. When air drying doesn’t suffice, a high-quality heater can dramatically increase drying speed when combined with a high performance fan and stirring machine.

Doors

Note that grain bin doors also vary in size, sometimes up to a few feet. A larger door provides convenient access for bin maintenance. Most manufacturers offer 44-inch, one-ring doors. Larger doors – up to 66 inches tall – are available.

Now that you know what to evaluate, inspect, and quote, there’s one last thing to keep on the forefront – the warranty.

Keeping Grounded

The safest place is on the ground. Naturally, any time you can avoid climbing to the top of the bin you reduce the risk of injury. Implementing a number of features on your grain bin will reduce the climbs necessary, and make the necessary ones safer:

Remote Lids

Remote Lids

Remote-controlled lids keep workers off of the bin roof by enabling them to open and close the bin from the ground. These are commonly standard on 15-foot to 27-foot roofs and are available as an option on larger diameter bins, as well.

Stairs

Bin stairs are a safer alternative to a ladder. Look for wider staircases and bigger platforms, which might not seem important until you’re 150 feet high on a windy day. To further increase safety at extreme heights, manufacturers have begun offering peak walk-arounds and roof stairs with handrails to prevent injury or falls. Again, with the added security, these accessories pay for themselves repeatedly.

Grain Gauge

A grain gauge is a cost-effective way of telling when your bin is full – or even how full it is if gauges are placed on multiple rings. This can also prevent overfilling.

There are no shortage of aspects, components, and fabrication elements to consider when making a grain bin purchase. From scouting the site to tightening the last bolt, plan for the future and you won’t be disappointed.

Warranty

Grain bins should last 40 to 50 years with very little maintenance. Manufacturers that build high-quality, long-lasting products offer lifetime warranties on certain parts like the roof or the bottom ring. For farmers, the warranty provides the peace of mind of knowing they’ve chosen a quality product, and if there are any problems, the manufacturer will be there to take care of them.

About the Author

By Trever Meier, Director of Sales & Marketing. Superior Manufacturing

Trever Meier is the director of sales and marketing at Superior Manufacturing. He grew up in southwestern North Dakota and worked on the family farm until he was 25. Meier has been in sales and manufacturing industries for 12 years.